Hot Products

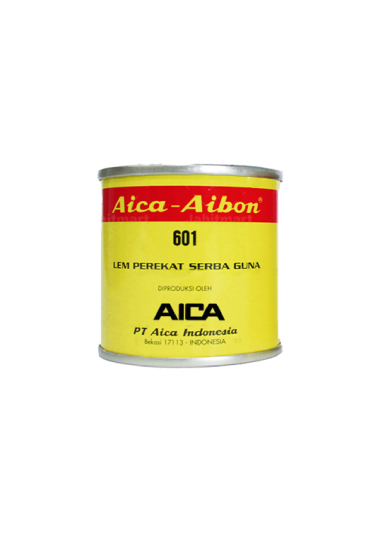

Aibon 601 (70 gr)

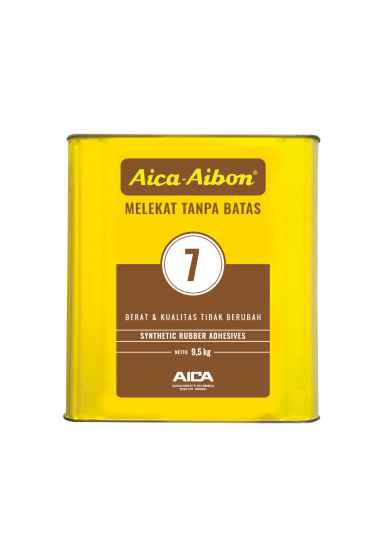

Aibon 7 (9.5 kg)

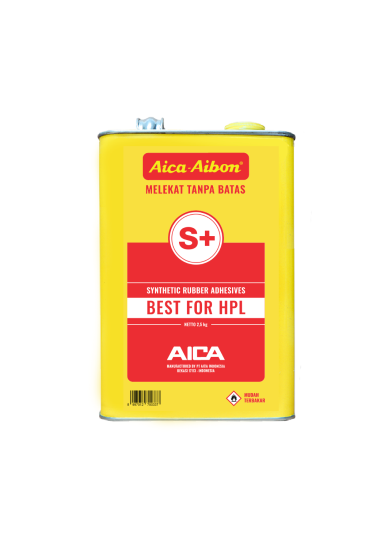

Aibon S+ (2.5 kg)

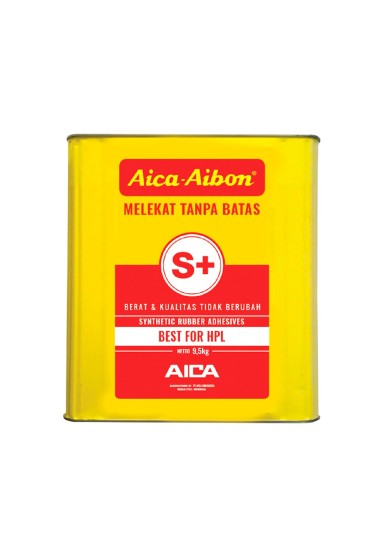

Aibon S+ (9,5 kg)

HAK-14038-ZM83

XKAF-14198-ZMN

XKAF-14038-ZMN

XKAF-14040-ZMN

XKAF-14146-ZMN

In the modern interior and furniture industry, MFC board is one of the most widely used materials. This material is known for its neat appearance, relatively affordable price, and easy installation. It's no wonder MFC board is often chosen for various needs, such as kitchen sets, wardrobes, work desks, and even room partitions.

MFC board stands for Melamine Faced Chipboard, which is a particle board (chipboard) coated with a melamine surface on both sides. The core of this board is made from compressed wood chips that are bonded using a special resin under high pressure and temperature. The surface is then coated with patterned decorative paper impregnated with melamine resin, creating a strong, smooth, and scratch-resistant layer.

Because it already has a finishing layer, MFC board does not require additional painting. This makes it more practical than other materials like plywood or MDF, which often require recoating to achieve an attractive final appearance.

There are several advantages of MFC board that make it popular in the furniture and interior design industry:

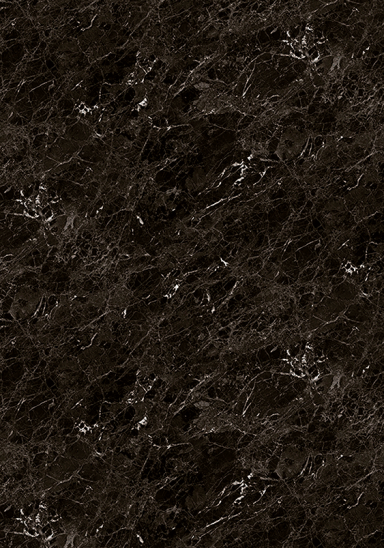

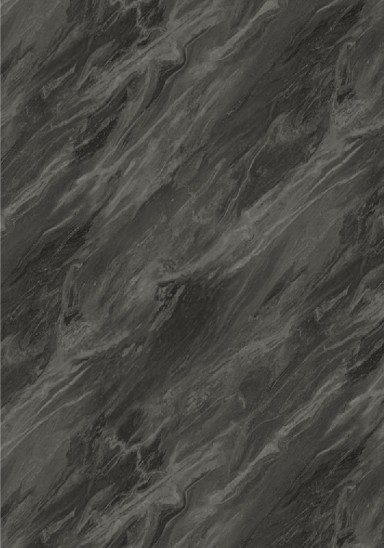

1.Aesthetic Appearance

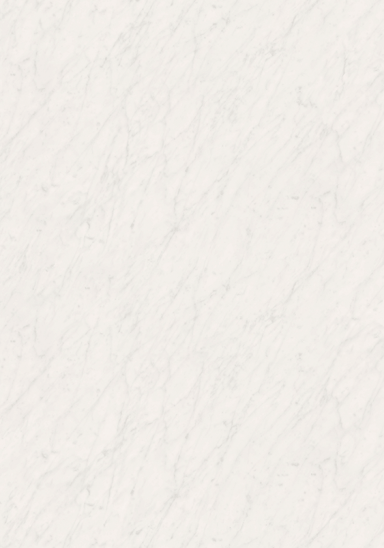

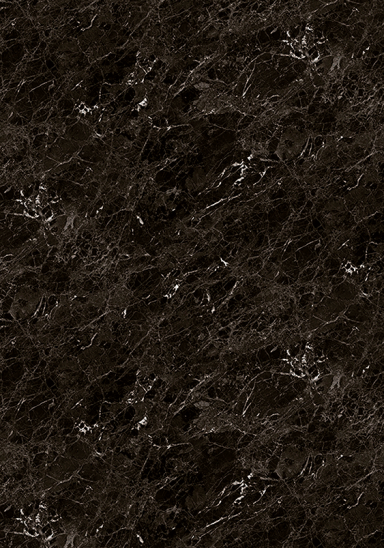

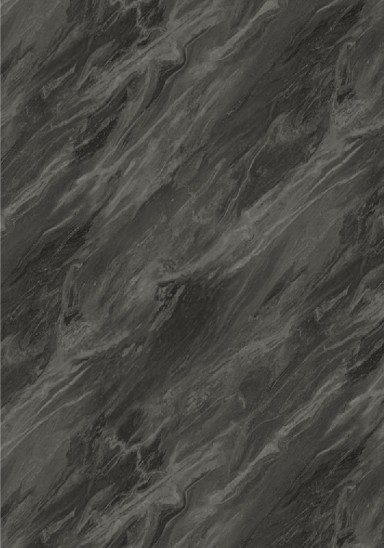

MFC board is available in a variety of colors and patterns, such as wood grain, solid colors, and even specific textures. This makes it easy for designers to match it to a room's concept.

2. More Economical Price

Compared to solid wood or high-quality plywood, MFC board offers a more affordable price while maintaining an attractive appearance.

3. Light Scratch-Resistant Surface

The melamine coating on MFC board makes the surface more resistant to light scratches and stains.

4. Easy Maintenance

Simply clean with a damp cloth to maintain cleanliness, without requiring special maintenance.

5. Stable Production Process

Because it is manufactured to specific standards, the quality and dimensions of MFC board tend to be consistent.

In general, MFC board specifications on the market meet the following standards:

Some manufacturers also provide MFC board with additional features such as moisture resistance for use in areas with higher humidity levels, such as kitchens.

MFC board has extensive use in the interior design world. This material is often used to make:

However, it is important to note that MFC board is less suitable for areas with direct water exposure or heavy loads without adequate support structures.

MFC board is a practical, economical, and aesthetic furniture material solution. With a pre-bonded melamine layer, MFC board offers easy installation and an attractive finish without the need for additional finishing. Understanding the definition and specifications of MFC board will help you choose the right material for your design needs and room function.

Need MFC Board? AICA MFC could be the solution! Learn more now by clicking the WhatsApp button in the bottom right corner of your screen or click here!

SHARE