Hot Products

Aibon 601 (70 gr)

Aibon 7 (9.5 kg)

Aibon S+ (2.5 kg)

Aibon S+ (9,5 kg)

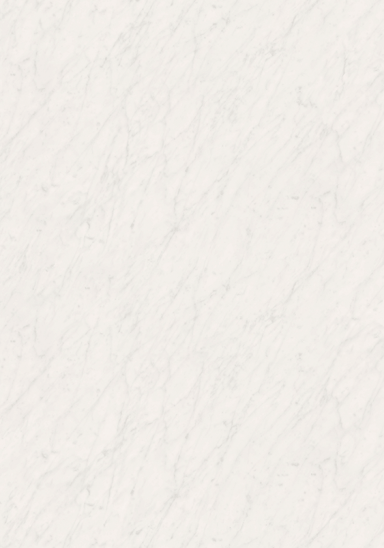

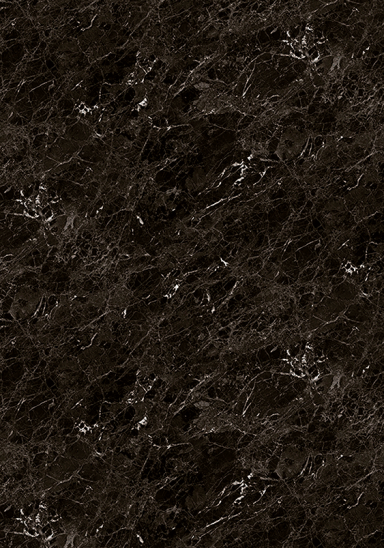

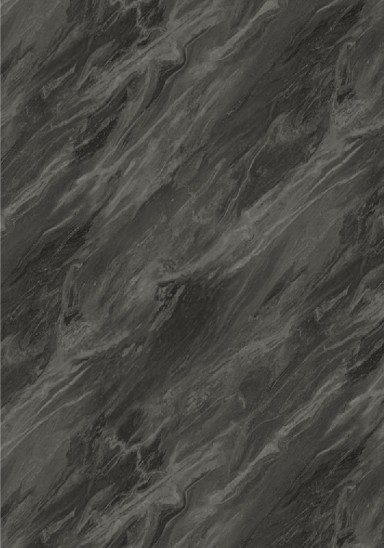

HAK-14038-ZM83

XKAF-14198-ZMN

XKAF-14038-ZMN

XKAF-14040-ZMN

XKAF-14146-ZMN

In the furniture and interior design industry, material selection is a crucial factor in determining the quality, durability, and final appearance of a product. Two frequently used materials are MFC and particle board. While they may seem similar at first glance, there are several key aspects that differentiate them. Understanding the differences between MFC and particle board will help you determine the most suitable material for your project needs.

Before discussing the differences between MFC and particle board in more detail, let's first understand their definitions.

One of the main differences between MFC and particle board lies in their finishing.

This makes MFC more practical and efficient in the furniture production process.

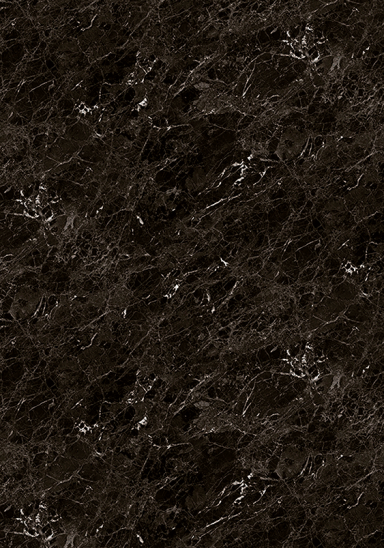

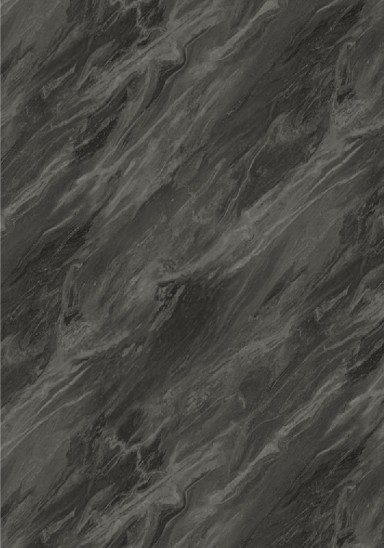

Visually, the differences between MFC and particle board are quite significant. MFC is available in a variety of colors and patterns, such as natural wood grain, solid colors, and even specific textures. Its surface is also neater and more uniform because it is manufactured in a factory to certain standards.

Conversely, raw particle board has a plain appearance and is less attractive if uncoated. Therefore, this material is more often used as the core layer or base structure.

In terms of raw material prices, particle board is usually cheaper than MFC. However, if you factor in additional finishing costs such as HPL, paint, or veneer, the total production cost of particleboard can approach or even exceed that of MFC.

Because it already has a melamine coating, MFC tends to be more time- and cost-effective, especially for mass production, such as kitchen sets and cabinets.

In terms of durability, the two are relatively similar because they both use wood particles as the base material. However, the melamine coating on MFC provides additional protection against light scratches, stains, and light humidity.

Uncoated particleboard is more susceptible to water and surface damage if not properly finished.

Understanding the differences between MFC and particleboard is also important in determining its use.

Simply put, the difference between MFC and particleboard lies in the finishing layer and its level of practicality. MFC is particleboard coated with melamine, making it more ready-to-use, aesthetically pleasing, and efficient in production. Meanwhile, particleboard is a base material that requires additional finishing processes before being used as finished furniture. By understanding these differences, you can choose the material that best suits your design needs, budget, and room function.

AICA Indonesia, through its Aica MFC product, offers Japanese-quality MFC boards coated with Aica's signature HPL decorative layer. Learn more about Aica MFC by pressing the WhatsApp button in the bottom right corner of your screen or by clicking the link here!

SHARE